Rubber lining piping is used in various industries, playing an important role, its lining is generally the use of rubber material, is a corrosion-resistant material, according to different usage conditions to choose the right material.

Rubber Lining When rubber lining pipe used in acid, alkali, salt conveyor system, we need to use acid and alkali performance and corrosion resistance are relatively strong rubber raw materials, such as butyl rubber, natural rubber and neoprene rubber lining, lining glue can be used hard glue, semi-hard glue or soft glue, these can also be used alternately, according to the requirements can also be multilayer lining glue.

Because rubber also has the characteristics of "strong elasticity, wear resistance", can reduce the transmission medium to the inner wall of the pipe wear, wear-resistant rubber lining pipe is also widely used as a mine pipeline, coal-fired power plant ash pipeline, chemical system with solid particles of liquid pipeline. If used in high temperature environment, to use high temperature resistant materials, such as butyl rubber, EPDM rubber, butyl rubber, etc., with corrosion resistance. Rubber lining pipe is widely used, its lining material selection according to the actual use of the selection of the appropriate rubber material.

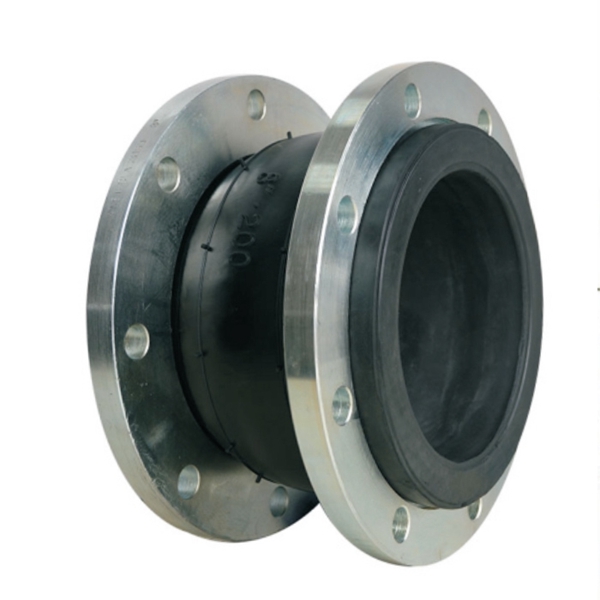

flange adaptor.jpg)